What Do The Numbers Mean On A 7018 Welding Rod

Camila Farah

This rod runs completely different from the 6010 and 6011 rods it is much smoother and easier.

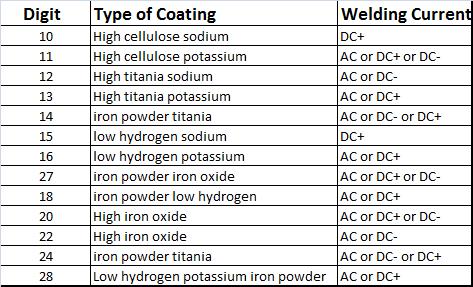

By looking at the classification we already know that the 7018 welding rod is an all position rod which produces weld beads which can withstand 70 000 pounds of stress per square inch. The last digit when read in conjunction with the penultimate digit indicates that it has an iron powder low hydrogen coating so it can be used with ac and dc currents. More of a drag rod the 7018 is also referred to as a low hydrogen or low high rod in the field. The electrode is a low hydrogen rod requires a moisture free environment so that the flux stays.

The electrode is considered more of a drag rod the 7018 is also commonly known as a low hydrogen or low high rod in the field. What do the numbers mean on a 7018 welding rod. For the 6011 electrodes they can be used with dcep and ac. Similarly the 7018 rods are coated with a low hydrogen flux mixed with potassium and iron powder compounds so this electrode works best with reverse polarity as well dcep and ac.

Welding electrode e7018 is a term that describes the electrode s tensile strength welding position flux coating and current. It is a fast freeze rod the puddle. A number of hardware shops field welders and home hobbyists often fail to stock the 7018 rods properly. E7018 electrodes are used in history.

RELATED ARTICLE :

- what can you put on a stye on your eye

- what can you eat if you have an ulcer

- what can i use to clean my washing machine

Within this classification procedure the very first 2 or 3 numbers suggest the tensile toughness of the bonded product which can be measured in kpi or kilo pounds per square inch. In e7018 70 symbolizes 70 000 psi or 70 kpi. The e7018 welding rod is one of the several electrode types with aws designation. For example the lincoln 7018 welding rod numbers show that the tensile strength is 70 000 psi.

Welding rods are manufactured by a number of. On the thickness of the material you are welding. Finally if the number ends in an r it means the rod resists moisture. After that will come an h number which indicates how much hydrogen will be diffused when you use the rod.

Finally the last number dictates the types of power sources you can use as well as the type of coating material of the electrode.

Source : pinterest.com